Thermoforming made predictable. AS9100 certified forming plus in-house tooling, rapid prototyping, and FAI documentation. Add CNC trimming, painting, and assembly under one PO. Expect clear timelines, a single point of contact, and repeatable quality from first article to full-rate production.

Have CAD and specs ready

Get a fast technical review and right-sized quote.

Need DFM guidance

Optimize draft, materials, and tooling approach before you cut.

I’m in procurement

ROM in 24–48 hours plus a vendor pack for quick onboarding.

Proof you can ship with

- 80+ years thermoforming complex parts

- Prototype to production under one roof

- Typical ROM in 24–48 hours

- First-article support and documentation

- Program-friendly scheduling and repeatability

Your path from first concept to stable production

Milestones, owners, and dates so there’s no guesswork.

-

RFQ in

What you get:

ROM range, feasibility read -

DFM optimization

What you get: Draft guidance, material advice, tooling approach (male/female), risk flags

-

Prototype tooling

What you get: Quick-turn tool, sample parts for fit, finish, testing

-

FAI and documentation

What you get: First-article review, measurement data, approvals

-

Production tooling

What you get: Durable tool, repeatability plan, QC checkpoints

-

Launch and scale

What you get: Firm schedule, communication cadence, change control

-

Ongoing support

What you get: Sustaining engineering, spares, finish/assembly continuity

Engineer to engineer support that derisks your part

Get manufacturability guidance before tooling so your first article fits and ships.

- Right-first-time tooling with informed male/female selection to avoid re-tools

- Material and thickness guidance to manage thinning and performance in use

- Draft and geometry optimization for clean release and consistent cosmetics

- Assembly planning upfront for paint, fastening, bonding, and sub-assembly

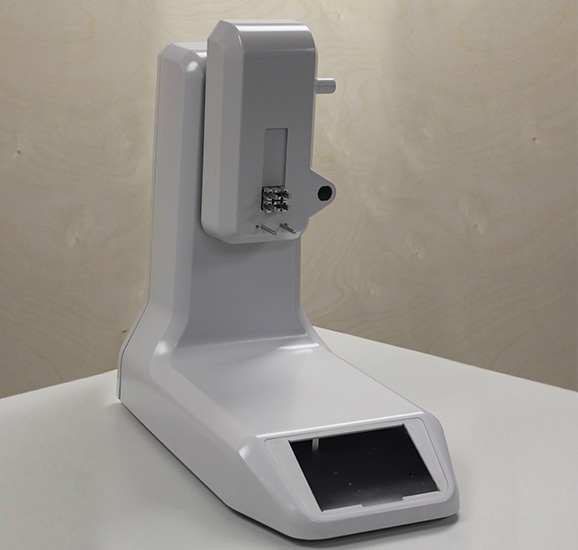

What you can build here

From complex covers to finished assemblies, under one roof.

-

Processes: Vacuum forming, pressure forming

Processes: Vacuum forming, pressure forming -

Tooling: In-house design for manufacturability and build

Tooling: In-house design for manufacturability and build -

Sizes and draws: Add max footprint and draw depth ranges

Sizes and draws: Add max footprint and draw depth ranges -

Materials: ABS, PC, PC/ABS, PMMA, HDPE, Kydex, TPO and more

Materials: ABS, PC, PC/ABS, PMMA, HDPE, Kydex, TPO and more -

Finishes: CNC trim, paint, texture, color match, EMI options (if applicable)

Finishes: CNC trim, paint, texture, color match, EMI options (if applicable) -

Assemblies: Bonding, hardware install, multi-part assemblies

Assemblies: Bonding, hardware install, multi-part assemblies -

Volumes: Prototype to long-run production

Volumes: Prototype to long-run production -

Docs & Quality: AS9100/ISO 9001:2015, FAI, PPAP on request

Docs & Quality: AS9100/ISO 9001:2015, FAI, PPAP on request -

Logistics: Kitting, JIT options, secure portal familiarity

Logistics: Kitting, JIT options, secure portal familiarity

Built for your environment

Industry-specific know-how that accelerates approval and scale.

Aerospace

Repeatability, FAI rigor, documentation control to fit your program cadence.

Industrial & Robotics

Durable housings and sub-assemblies with fast DFM and proto-to-production cadence.

Mass Transit

Impact resistance and finish consistency for fleet-scale rollouts.

Medical & Lab

Clean finishes and documentation readiness for regulated environments.

Automotive & Mobility

Cost-effective covers and enclosures with reliable scale-up plans.

From Startup to Enterprise, Small Runs to Inventory Management, Leading Brands Have Trusted Us Since 1946: